|

|

The display next to the gold park's main entrance |

Located in Goldstream Valley on the Old Steese Highway just minutes outside of Fairbanks, Alaska, Gold Dredge #8's Historic Park is definitely one of interior Alaska's top tourism sites. With tens of thousands of tourists visiting this site each summer.

For information on park hours and current prices Call: (907)-457-6058

Owned by Holland America Tours Gold Dredge #8 offers guided tours of their museums and the grounds. During which you'll then see a 20 minute film presentation containing actual footage of the dredge when it was still in operation. You'll then be briefed on the art of gold dredging the use of hydraulic mining points, and hydraulic mining. You'll then you begin your tour of Gold Dredge#8 and upon completion of it you'll be given a demonstration on gold panning and then be handed a pan so you can try it out for yourself.

I might add that the gold park also has a very nice gift shop, and assay office, a snack bar as well as a fabulous full sized banquet hall.

|

Beginning from left to right next to the railroad spur line there are 3 warehouses. The small square just below them is a huge crane. The next group of buildings included 2 crew bunk houses, their dining facilities, the Dredgemaster's house, a bathhouse, and the mining operation's main office. To the right of them is Gold Dredge #8, and the park's main dining facilities. The small rectangular structure next to that is the assay and the remaining four structures on the right side are the paymaster's office and the pavilions where you pan for gold. |

|

In this photo we see the mine's main office on the left. To the right is the Dredgemasters quarters and in the background is one of the crew's bunk houses. |

One of the things that I liked so much when I visited Gold Dredge #8 was that there are several options to chose from, as opposed to one set itinerary.

For example you can go on a hour long guided tour of the facility. During which you would see a 15 minute film containing historic footage of when the gold dredge was still in operation. After which your guide would show you actual pieces of era mining equipment explain their use and then take you on a complete tour of the actual gold dredge itself.

A second option is to skip the tour and just use their gold panning facilities. This ever popular choice caters to those first timers who prefer panning for gold -- as well as the many satisfied customers who come back time and again. I might add here that Gold Dredge #8 is the only operation in the area where you literally can pan all day if you so chose.

Which leads us now to the third option is which I might add is the most popular by far. Taking a guided tour along with gold panning. In this tour you get to see the film, you get the guide showing you the equipment, and the personalized tour of the gold dredge and then everyone gets handed a gold pan and a bag of pay dirt (some of the local gold laced soil). You then get an up close and personal demonstration on how to pan for gold and help panning should you need it. After which you can go over to the assay office where they while weigh out your gold and tell you how much it's worth according to the latest gold prices. All of which take from about an hour and a half to two hours.

So you may well ask what exactly is a gold dredge? A typical gold dredge like the one pictured below has two major components first is the pump (usually powered by a small gasoline engine) which is used to draw water, sand and gravel from the bottom of a stream bed or pond. Which is then run through the gold dredge's second major component the sluice box. Which is usually several feet long and contains a series of small steps called riffles over which the sand and gravel are washed to separate small nuggets and placer gold. And if all goes well when you shut your machine down you'll find concentrations of gold lodged against the sluice box's riffles.

|

The particular gold dredge depicted above is a 3" gold dredge made by Keene Industries. I found the photo on Danny the Dredger's Australian gold dredging web site. If you'd like to read more about gold dredging and other equipment used for gold panning just click on the image above.

Gold Dredge #8 is impressive to say the least. Standing five stories tall and over 250 feet long from the front edge of its gang line of 3 cubic yard ore buckets, to the massive chute at it's rear from which it expelled mining tailings.

Between 1928 when it was first put in service and 1959 when it ceased operation this juggernaut had mined over 7.5 million ounces of gold.

|

In the picture you can see the huge piles of tailing behind Gold Dredge #8 |

Gold Dredge #8 was actually one of four gold dredges that had been run the the F.E. Gold Company in Fairbanks.

I had thought that this massive machine had been steam powered. My first surprise came when my tour guide informed we that Gold Dredge #8 as well as the others were electric.

She then went into detail of how the F.E. Gold company had built a power plant in the city of Fairbanks on Illinois Avenue and had run a giant extension cord from which to run their dredges. I might add that this same electric power plant is still in use in Fairbanks today almost 100 years later. Run now by Golden Valley Electric the plant has changed hands and been refurbished several times since it was first constructed.

Another historic point of interest was that in order for them to work the gold fields they needed an immense amount of water. At first they constructed what was called the Davidson Ditch. a shallow canal used to divert water from the Chena River to the mining claims. However due to Fairbanks long cold winters reopening the ditch in spring and keeping it from freezing in late fall inevitably shaved weeks off the mining season. Faced with this staggering loss of revenue the F.E. Mining company built a pump house on the bank of the Chena River. The building contained 10 gigantic pumps each of which could put out 6000 gallons of water per minute as well as some heat generation equipment to prevent the water from freezing in early spring and late fall. The water was then down a pipeline along the Davidson ditch where it could be used to wash away the overburden or muck as they called it and to replenish the water in the ponds the gold dredges floated in.

The pump house remained in service between 1933 and the 1960's. After which it was eventually purchased in 1977 and became one of Fairbanks premiere eaters The Pump House Restaurant. Then 1n 1986 the site became a national landmark.

On to the Dredge

Gold Dredge #8 is actually quiet an interesting piece of engineering. Built on top of a huge barge as I mentioned it wasn't steam powered, and for that fact it possessed no propulsion system of its own. Its only moving parts were the gang buckets in front of the barge and a large cement mixer- like rotating steel drum containing thousands of quarter inch holes through which the water, sand, silt, and find gold flowed through. And the conveyor belts which then were used to carry out the rock and debris.

|

Looking down from the ship's control room we see the gang buckets as they would have been returning to the dredge laden with rock and gold laden soil. If you look carefully on the right side of the photo is a white measuring stick. About a half inch up from the bottom of its right side a black indicator. This was used by the Dredgemaster to determine how deep the gang buckets were digging. I am told that the optimum depth for this particular dredge was 28'

<-----Depth Indicator |

Unlike anything else I have ever seen the way that the dredge maneuvered itself was with the use of two stout cables anchored in the ground at 45 degree angles on opposing sides of the gang buckets. The barge was then slowly winched back and forth in a pendulum motion so that its 3' wide gang buckets could slowly eat away at the lead edge of the pond. The idea being that in order for the dredge to move it had to move the pond first. So here you have this giant piece of mining equipment which in essence is digging a canal and filling it in again behind itself.

|

We are now looking at the gang buckets from the front, right where the buckets would have broke up through the ground. As you can see the buckets then rose from ground level almost four stories before dumping their load inside the dredge for processing. It should also be noted that the gangway on the left was not there when the dredge was operating. |

|

I am told that the pond and Gold Dredge moved at the rate of about 500 feet a month. Needless to say during the course of Gold Dredge #8's 31 years of operation the buildings, water supply and power supply were moved all up and down Goldstream Valley at one time or another.

|

Entering inside the dredge itself our first stop on the main deck is to view the large cement mixer like cylinder which was used to separate the rock from the soil and gold. If you look closely at the hole in the floor of the photo you can just make out a horizontal double set of rivets running up the cylinder where the metal plates were joined together. <---- Riveted Main Sluice Cylinder If you then look up into the second fenced off area the cylinder is a little easier to see. As long as the largest mobile home made the cylinder was approximately 90' long and 12' in diameter. |

Inside the dredge its only boiler was used in early spring and late fall to keep ice from building up on the dredge via a series of pipes mounted on the walls around where the gang buckets first dump the rock and gravel.

In this photo we see actual components from Gold Dredge #8's giant sluicebox.

When the dredge was in operation the mat on top contained a small amount of mercury in each one of the holes

On top of the mat was a series of wooden riffle boards like the one depicted the lower part of this photo.

The Sluice box room

In the center of the main deck of the dredge directly below rotating cylinder under lock and key was the dredge's sluice box room. Behind the wrought iron bars and heavy duty mesh wire fencing was this was the most secure part of the operation.

At this point the tour guide enters the 12'x14' chamber and explains in great detail the how the sluicing system seperated the fine gold from the silt and sad worked by uses of a system of removeable riffle board inserts and mercury mats.

Once a month the dredge would be shut down for about two hours to remove the gold. During this time the wooden riffle boards (Depicted in the lower half of the photo above) would be carefully removed and the fine gold rinsed off them.

The next step was to recover the placer gold trapped in the hundreds of holes each of the mercury mats (A sample of which is depicted in the upper half of the photo above.) When placed into the sluice box each of the hundred or more round holes these mats are filled about half way up with mercury. During the sluicing process the mercury is heavy enough that it doesn't wash out of the holes as the water and sand run over the top of it. And one of the peculiar properties of mercury is that when small gold fragments and flakes come in contact with it they bond with it. It is in these mats that the heaviest concentrations of gold are found. This gold mercury mixture is called amalgam. The amalgam is then carefully ppoured and scraped into several milkbox sized security containers.

Incidently mercury extraction techniques are still used today in Fort Knox and other area large scale gold mining operations.

Once they had finished with the mercury mats, there was still a layer of coconut matting beneath that that had to have the gold hand washed out of its fiber. And then last but not least they would scrape out the sluicing troughs getting out the last few ounces of gold before putting the whole thing back together once more and turning the dredge back on.

The amalgam and gold concentrates would then be shipped via armored car to F.E. Company in Fairbanks where it would be smelted. After which the gold would then be poured into 100 ounce ingots which were in turn shipped to the US Government in Fort Knox, Kentucky. All for the almost unbelievably low price of $28.00 dollars an ounce.

|

This shot was taken in the ship's wheel house.

And interestingly enough I spotted a pendulum style plumb bob on the wall. And as you can see as the barge now rests it's actually listing about 5 degrees to port |

|

|

This is another photo inside the ship's wheel house Silhouetted in this photo are the dozens of level controls that the Dredgemaster used to control the speed and depth of the gang buckets and the orientation of the barge. |

| In this view we are now looking up at the exterior of the wheel house from the gangway below |  |

|

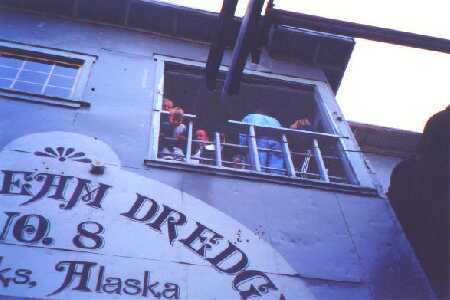

This next shot was taken up on the deck of Gold Dredge #8's dining facility. The window belonging to the wheel house is the larger one to the right. |

|

After hearing the lunch bell jangle several times and watching a few hundred tourists go to eat there I decided to take a look for myself. And I just about fell on the floor when I entered the place. It was as beautiful as a cruise ship. Even with all that had already eaten nothing was out of place. But hey, the place after all is run by Holland America. |

|

To Continue Your Virtual Dredge Tour

Gold Dredge #8

| Gold Dredge #8 |

Jan. | Feb. | Mar. | Apr. | May | June | July | Aug. | Sept. | Oct. | Nov. | Dec. |

| Tourist Season | 15th | 15th |

NOTE: Whether Gold Dredge #8 is open in mid -May and mid- September depend on local weather conditions. If you are in fact planning a trip to Fairbanks in mid- May or mid-September you should call Gold Dredge # 8 in advance to see if they are will be conducting tours during your visit.